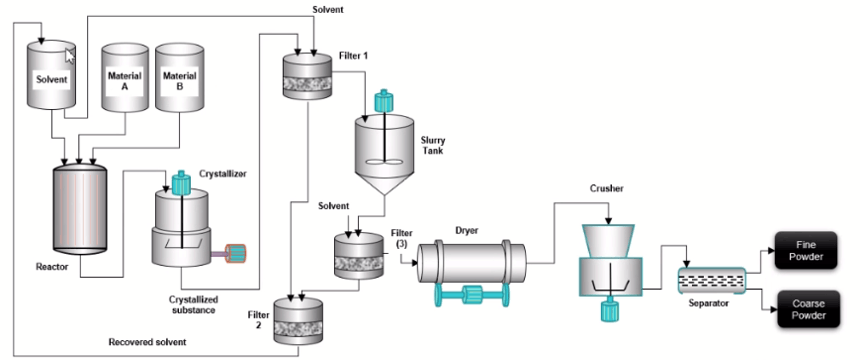

How does this process work?

Acme Corp makes tablets that require fine particle powder. (Coarse powder needs further crushing.)

Fine particles are good

If a batch has over 90% of fine particles, it's a good batch.

Coarse particles are bad

Bad batches have less than 90% fine particles. They must be flagged in advance to avoid wastage