AI-Driven Defects Detection

with 95% Accuracy

AI-Driven Defect Detection for Quality and Efficiency

Manufacturers Are Facing

Losses Due to Ineffective Quality Checks

Manufacturing Defect

Defects in manufacturing processes.

Quality Issues

Quality issues due to defects in raw materials.

Increased Costs

Increased costs due to rework and re-inspection.

Customer Loyalty

Customer loyalty is at risk due to manufacturing flaws.

Implement Defect Detection Solutions

Get Comprehensive Defect Detection For Manufacturing Processes

Our AI-powered solution, Defect detection, takes your manufacturing processes to the next level. It is designed to boost efficiency and accuracy with its multiple applications, including inventory management, defect detection, shop floor hygiene and safety, automated inspection, and adherence to SOPs. Say goodbye to manual inspection methods and hello to significant advantages.

Industries We Serve

Gramener’s Defect Detection Solution, with its advanced analytics and machine learning capabilities, empowers pharma firms globally to improve quality assurance and control, reduce costs, and enhance efficiency through data-driven insights, scalability, and adaptability for seamless compliance and reporting.

Gramener’s Defect Detection Solution, with its advanced analytics and machine learning capabilities, empowers pharma firms globally to improve quality assurance and control, reduce costs, and enhance efficiency through data-driven insights, scalability, and adaptability for seamless compliance and reporting.

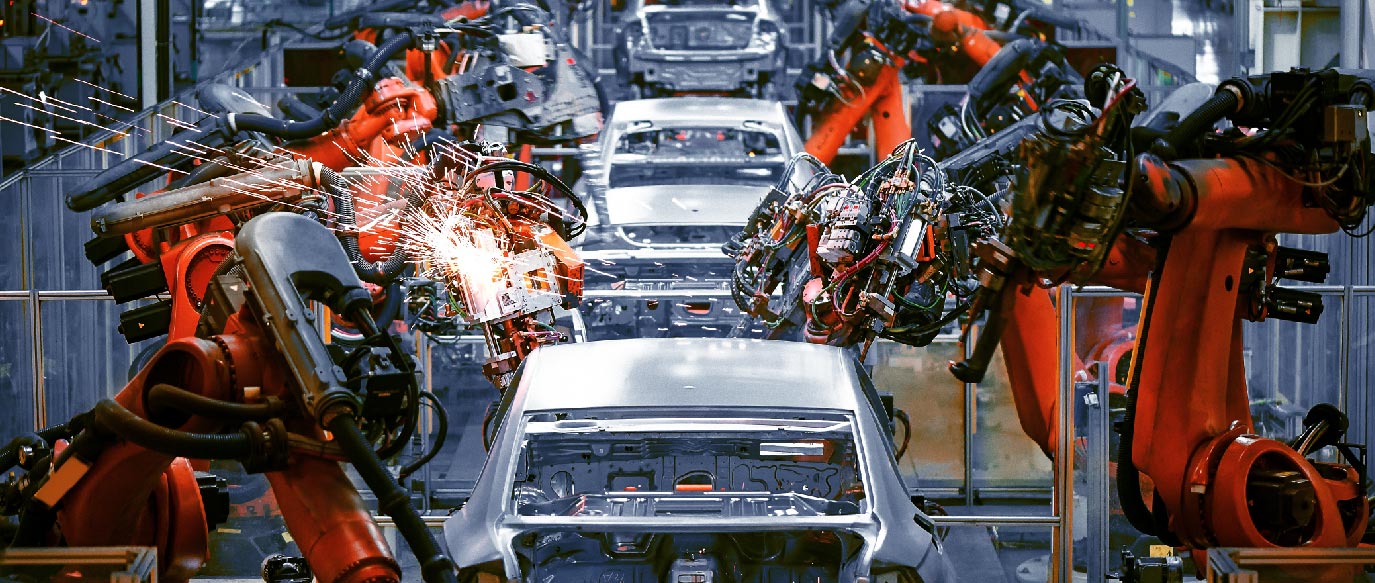

Gramener’s Defect Detection Solution leverages computer vision, machine learning, and data analytics to provide actionable insights for predictive maintenance. It helps automobile manufacturers/automobile companies to increase efficiency, reduce costs, improve product quality, safety, and operational efficiency.

Gramener’s Defect Detection Solution leverages computer vision, machine learning, and data analytics to provide actionable insights for predictive maintenance. It helps automobile manufacturers/automobile companies to increase efficiency, reduce costs, improve product quality, safety, and operational efficiency.

Gramener’s AI-powered defect detection solution helps improve food and beverages companies to control quality, detect contaminants, increase packaging integrity, reduce costs, and provide insights for process optimization, resulting in improved product quality, safety, and operational efficiency.

Gramener’s AI-powered defect detection solution helps improve food and beverages companies to control quality, detect contaminants, increase packaging integrity, reduce costs, and provide insights for process optimization, resulting in improved product quality, safety, and operational efficiency.

![]() To optimize quality control in the semiconductor and electronics industry, Gramener’s Defect Detection solution uses AI to offer high-resolution imaging for defect detection, automated inspection for efficiency and data-driven insights for process optimization, leading to improved product quality, enhanced reliability, and operational efficiency.

To optimize quality control in the semiconductor and electronics industry, Gramener’s Defect Detection solution uses AI to offer high-resolution imaging for defect detection, automated inspection for efficiency and data-driven insights for process optimization, leading to improved product quality, enhanced reliability, and operational efficiency.

Gramener’s Defect Detection solution leverages AI to transform printing and packaging operations by offering automated visual inspection for print quality and packaging defects, increasing efficiency, reducing costs, and providing insights for process optimization. This results in improved product quality, enhanced reliability, and operational efficiency.

Gramener’s Defect Detection solution leverages AI to transform printing and packaging operations by offering automated visual inspection for print quality and packaging defects, increasing efficiency, reducing costs, and providing insights for process optimization. This results in improved product quality, enhanced reliability, and operational efficiency.

Benefits

Savings

Manufacturers benefit from

reduced labor

and other

operational costs

Quality

Production volume increases without

compromising quality

Reduce Delays

Preventing defective parts by delaying

assembly lines through early error detection

Improved TAT

Improved manufacturing efficiency and

reduced turnaround times

Accurate

Delivering better accuracy

rates than the human eye

Improved Processes

Identifying patterns in historical data to predict and

improve future production processes

AI visual inspection works in 4 easy steps

We automate end-to-end process implementation for you, removing the intermediaries & ensuring that no manual

intervention is required. We offer a turnkey solution that easily integrates with your existing processes.

To collect the data, all you need is a camera, high-speed internet & storage space. Our data analytics model can be

trained to detect defects with a high degree of accuracy.

Step 1

Install cameras in the

production line

Identify right location to install the cameras and maintain proper distance & angle for a clean shot

Step 2

Capture & store

the images

Capture 200+ images for defect-free & defective products, and label the images.

Step 3

Train analytics

model

Feed the analytics engine with labeled images. Train the model to analyze the photos & detect flaws.

Step 4

Deploy the

solution

Implement the solution in the production line and scale it as and when required

Our Resources

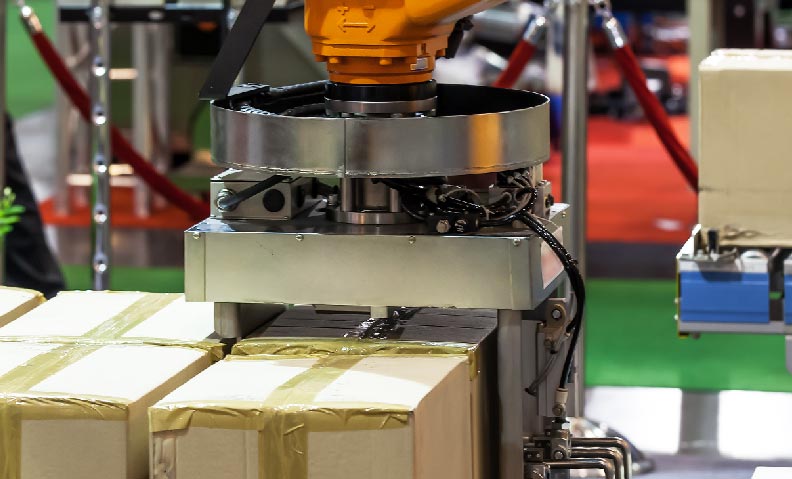

Defects in E-Commerce Packaging

Our solution monitored packages with real-time image analysis, detecting defects and flagging defective packages for removal and re-inspection. This ensured that only defect-free packages were processed for end-delivery, enhancing product quality, customer satisfaction, and operational efficiency.

Removing Defective Terminal Block

Deep learning AI solution for quality inspection achieves 100% accuracy in defect detection by efficiently positioning 25 different variants based on shape and size for thorough inspection. Generated consolidated reports for defect analysis and integration with an automatic rejection system.

Damaged Biscuits in Biscuit Packaging

Leveraged deep-learning AI software with real-time image analysis to inspect biscuit post-baking and while on the conveyor belt. Achieved 99.9% accuracy in ejecting faulty products. Our solution ensured consistent and reliable defect detection while streamlining production processes.

Schedule a Demo with us