Step into the Future with Digital Twin Solutions

with digital twin software

Unlocking Possibilities with Digital Twin Services pharma

Design, manage, and optimize your physical processes with the alliance of innovation and reality.

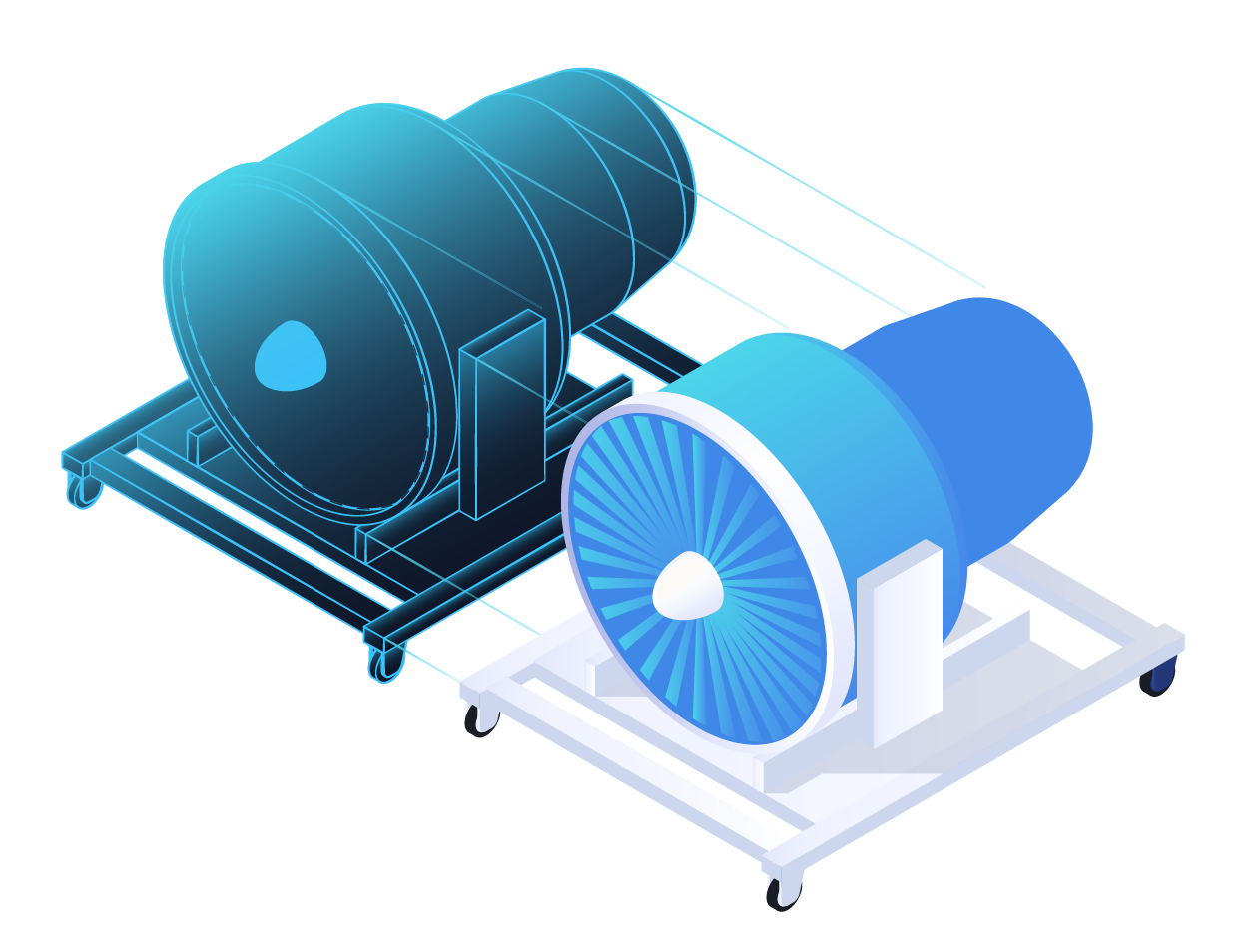

Gramener’s digital twin software – is a virtual representation of your physical object, process, or system, is not just a simulation; it’s a dynamic, real-time counterpart that mirrors your physical processes, offering monitoring, insights, analysis, and opportunities for enhancement. A digital twin creates a virtual replica of equipment, components, or processes that help organizations control manufacturing in real-time and predict failure points in advance.

Our digital twin solutions are rapidly changing

the scope of operations management

Why do you need Digital Twin Software?

Precision in Design and Development

Create, test, and refine your processes in a virtual environment before you begin to deploy them physically, thereby reducing associated costs and minimizing risks.

Real-time Insights and Monitoring

Keep tabs on the performance of your assets and processes in real time. Detect anomalies, predict failures, and make informed decisions that keep operations running smoothly.

Optimize your Performance

Simulate and understand how your systems function under various conditions. Fine-tune operations, identify bottlenecks, and maximize efficiency for improved overall performance.

Predictive Maintenance

Anticipate maintenance needs before they turn into costly breakdowns and extend the lifespan of your manufacturing assets while reducing downtime.

Better Decision-making

Equip yourself with data-backed insights that guide strategic decisions such as operational planning, expansions and enhancements, to name a few.

Our Digital Twin Solutions can aid you achieve all the above

It has four components to guide clients towards enhanced visibility & control.

It is a dynamic dashboard that mimics behaviour of a machine or production line in real-time and identifies quality of the product being processed

The variations, once identified, are immediately notified to users with recommended actions.

Along with the Process Monitor, the Simulator provides enhanced ability to users to perform root cause of problems already occurred

It empowers users to play with endless combinations of factors that impact the production process and predict product quality in advance.

Our live digital twin projects

Industry: Pharma manufacturing

Reduced machine set up time by 67%

We helped a generic drug manufacturer reduce manual interventions needed for machine set up, that previously led to scrapped tablets (>10k+) and wasted efforts. Enabled with our digital twin solution, operators can now set up the compressor appropriately and ensure correct tablet hardness, thickness and weight as the outcome. The solution is based on predictive analytics leveraging classification models.

Industry: Pharma manufacturing

Saved cost over $2M

A global drug manufacturer struggled to maintain high & consistent production of the Golden Batch. Our digital twin solution helped the client to establish a relationship between operational and material parameters and improve production yield for 10 compounds. The solution is based on advanced statistical analysis and machine learning models.

Industry: Mattress manufacturing

Increased mattress production yield by 3%

A global mattress manufacturer was struggling to improve the yield & performance of the production line. Our digital twin solution enabled the client to derive actionable insights from the data generated during the production process and secure better control over humidity & temperature factors that improved both mattress quality & production yield.

Why choose Gramener’s Digital Twin services?

Expertise

With over a decade of experience in advanced data analytics and AI, we're at the forefront of digital twin technology.

Innovation

Our solutions are designed to cater to the evolving needs of modern manufacturing.

Customization

We understand that every business is unique; our digital twin solutions are tailored to your custom requirements.

Results-Driven

We're committed to delivering tangible business results that will positively impact on your bottom line.

Our Resources

Embracing The Digital Twin Technology

Optimize your shop floors, warehouses, packaging operations, overall equipment efficiency & more with digital twin technology.

Aiming Zero-Waste Drug Manufacturing

Gartner’s study reveals that 75% of organizations implementing IoT already use digital twins or plan to within a year.

What is Digital Twin in Manufacturing Industry

Digital twin in manufacturing processes is redefining the processes and systems for better results.

5 Ways to Improve Production Performance with Digital Twins

An end-to-end supply chain will connect more humans and things and break up supply chain silos.

Implementing Digital Twin for Predictive Maintenance

Manufacturing businesses can enjoy a lot of advantages by opting for digital twins in predictive maintenance.

Schedule a Demo with us